Plate heat exchangers are used for transferring heat between two fluids. They work by covering the fluids with metal plates. This feature helps in the transfer of heat and provides a high temperature response. Plate heat exchangers are commonly used in combination boilers. The high heat transfer efficiency of a small plate heat exchanger has greatly increased the domestic hot water flow rate of combination boilers.

A heat exchanger is a type of containment vessel that works to transfer heat from one fluid to another. It’s commonly used to keep a pipe containing a liquid cool. The walls and outer casing of pipes are made of various materials with high thermal conductivity to allow the flow of heat. These components are usually reinforced with plastic or coated with a thermal insulation material.

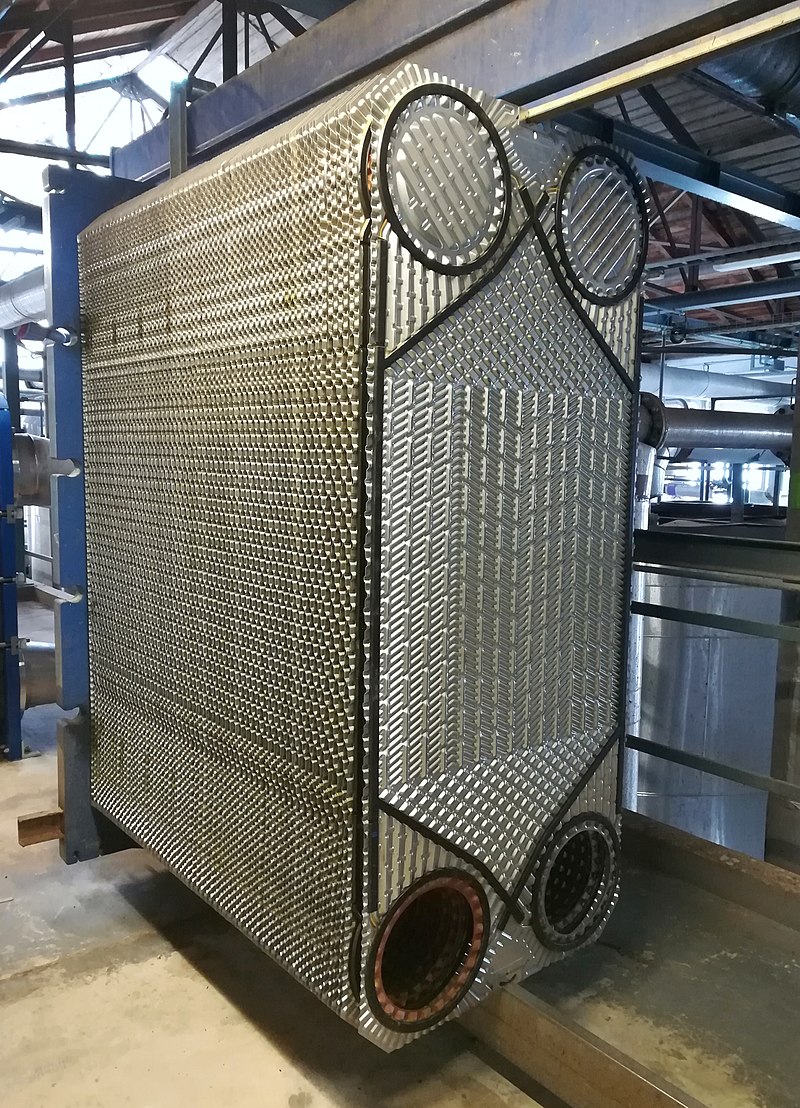

The plate heat exchanger is a type of heat exchanger that is commonly used to transfer heat from high-pressure fluids to low-pressure ones. It is a specialized design that can handle different temperatures. The plates used in a heat exchanger and plate are pressed by one piece of metal. Usually, these components are made from 304L stainless steel.

The plates are often lined with rubber seals which are inserted into a section around the edge. These troughs are arranged so they can interlink with the other plates and form a channel with gaps of up to 1.5 mm. The arrangement of these troughs allows for the fast exchange of liquid. The troughs help maintain a turbulent flow in a liquid and maximize the heat transfer in a fuel cell. This process can be achieved by achieving a high degree of turbulence.

On the other hand, all plate heat exchangers have the same exterior appearance. However, the inner working surface of the product is different from the outer surface. This is because it uses different sealing technologies and has different design elements.

An important aspect to consider when evaluating a heat exchanger is the type of corrugation within the system. There are two main types of corrugations that are commonly used within the heat exchanger: intermating and chevron. There are so many ways to improve the efficiency of heat exchangers that it is extremely unlikely that any of them will work seamlessly with a commercial simulator. This article provides a brief overview of the various steps involved in the development of new heat exchangers. It also talks about the various factors that should be considered when choosing a heat exchanger.

Periodic cleaning is the most efficient method to remove dirt and waste from the heat exchanger. This procedure involves draining the plate and its fluid to expose the dirt and waste that have accumulated within the system. From both sides, the water should be flushed out to completely clear the system. This process should be performed in the opposite direction to maintain its optimal results. After draining the tank, a cleaning agent should be used to remove the grime and prevent the system from running.

Plate heat exchangers are commonly used in various applications due to their design. Although they can provide high heat transfer, they also require low pressure drops to achieve their intended performance.

There are many facets of Reynolds numbers and chevron angles that exist for plate heat exchangers. Corrugated plate heat exchangers have a narrow path between the plates, which can prevent the flow from flowing smoothly. This design feature makes them require more pumping power than other types of heat exchangers. Fining is a technique that involves applying turbulence to the inner and outer finning tubes. This technique can help increase the heat transfer film coefficient of a given liquid. The higher pressure drop helps in achieving an added efficiency. However, the height at which the fin should be placed is also important for achieving a high heat transfer efficiency.

Tabulators, inserts, and static mixers are used to facilitate vibration and heat transfer. With high viscosity fluids, these devices are usually most efficient. However, for liquid heat transfer, they can increase the pressure by up to five times.

Sign up for newsletter and recieve updates on new products, specials, and news.